How Smart Tooling can offer better quality, lower cost, and throughput advantages over traditional fabrication methods for co-cured composite structures.

Using Smart Tools to Create Multi-Chamber Control Surfaces

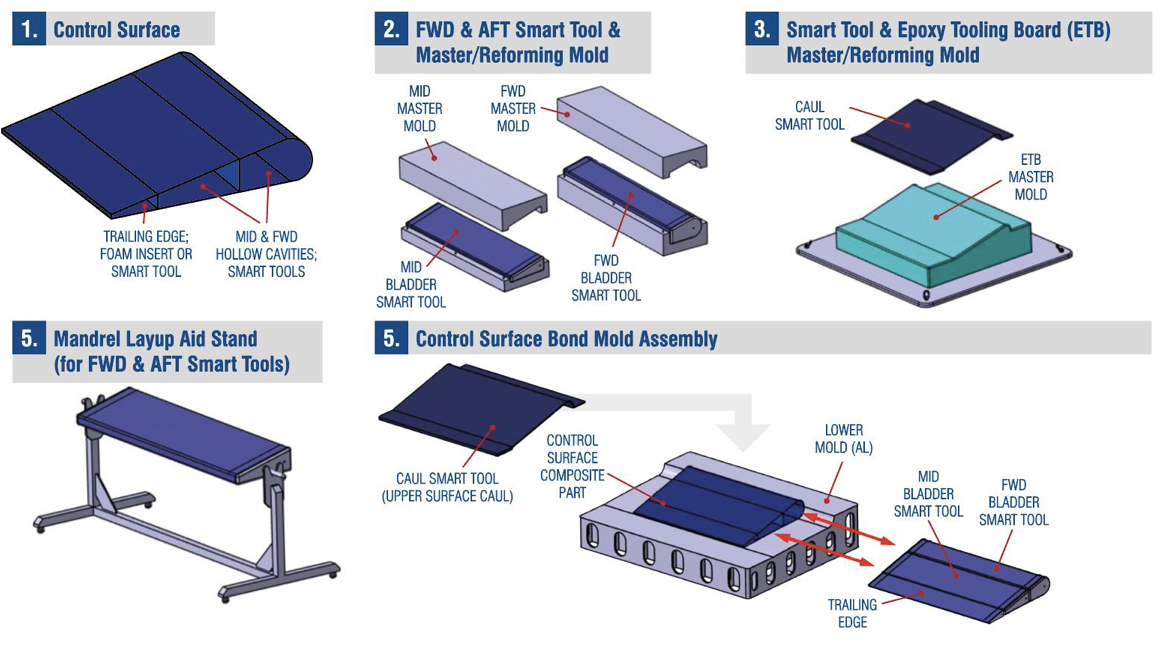

Using Smart Tools to create co-cured composite structures such as a multi-chamber control surface improves part quality by allowing the customer to lay-up on male tools. Traditional fabrications require layups to be done in a female mold, making proper placement and debulking difficult and even more difficult for parts with complex geometries and acute angles.

In a bladder application, the laid up Smart Tool is placed in a female cure mold and becomes elastic during cure, allowing it to transfer internal pressure to the composite laminate to insure good compaction and uniform resin flow.

After the cure, the Smart Tool is still in an elastic start, which allows the tooling to be easily extracted using low force from the cured composite control surface. The tool is then placed into a heated reforming mold and vacuum is applied to reform the geometry of the Smart Tool for future use.

This workflow can be visualized below:

Smart Tooling provides formable, reusable tooling solutions for manufacturing composite parts with complex geometries for the aerospace & defense industry. Smart Tools improve quality, reduce labor hours, decrease consumables, and increase throughput – essentially, Smart Tools enable the manufacturing of composite parts better, cheaper, and faster.

Smart Tooling’s Shape Memory Polymers are designed to be aerospace-grade RIGID epoxies at room temperature, and highly FLEXIBLE elastomers when heated, eliminating the need for expensive, laborious, tedious, dirty, and challenging solutions such as melt-out foam, metal breakdown tools, rubber bladders, or washout tooling.

We also deliver comprehensive solutions. We offer total solutions for the manufacture of your composite part, including custom tooling engineering and design, fabrication of molds, Smart Tooling fabrication, initial composite part manufacturing, custom standard operating procedures, onsite start-up support and training, and any future training if required.

For more information on how Smart Tools work and their applications, click here.

Share this Post