Learn more about Smart Tools that act as Mandrels in this core product overview.

Smart Tools that act as Mandrels are a formable, reusable tooling solution for manufacturing composite parts with complex geometries that improve quality, reduce labor hours, decrease consumables, and increase throughput.

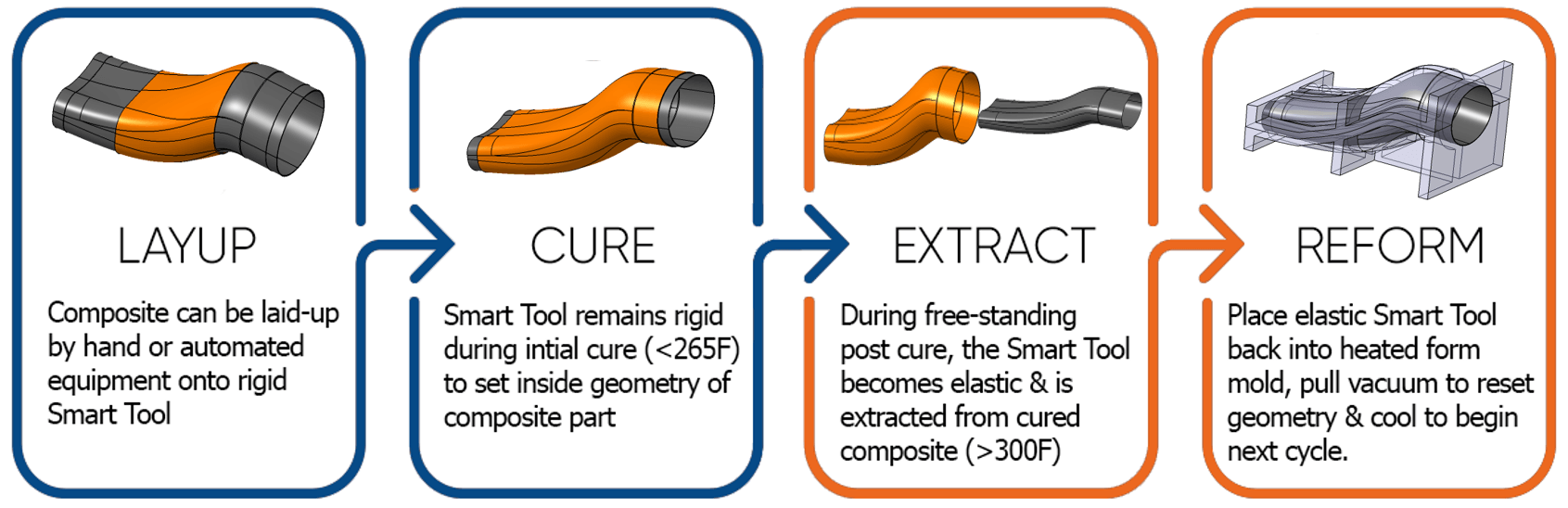

THE PROCESS

- LAYUP – Composite can be laid-up by hand or automated equipment onto rigid Smart Tool

- CURE – Smart Tool remains rigid during initial cure (<265°F) to set inside geometry of composite part

- EXTRACT – During free-standing post cure, the Smart Tool becomes elastic & is extracted from cured composite (>300°F)

- REFORM – Place elastic Smart Tool back into heated form mold, pull vacuum to reset geometry, and cool to begin next cycle

Smart Tools that act as mandrels are manufactured to the inner mold line (IML) geometry of the composite part and are rigid at room temperature. After a release film is applied, composite material can be placed directly onto the Smart Tool.

Smart Tools that act as mandrels during cure are perfect for two-stage composite cures. During the initial composite cure at 121°C (250°F), the Smart Tool remains rigid and sets the inner mold line geometry of the composite part. Then, as the temperature is being elevated to perform a post-cure of the composite part at 177°C (350°F), the Smart Tool becomes elastic and can easily be removed from the cured composite part, reformed and reused.

Smart Tools allow composite material to be laid up on the male Smart Tool and cured, eliminating the need to layup into angular female cavity cure molds that are prone to bridging and results in composite part porosity and resin rich areas.

We also deliver comprehensive solutions. We offer total solutions for the manufacture of your composite part, including custom tooling engineering and design, fabrication of molds, Smart Tooling fabrication, initial composite part manufacturing, custom standard operating procedures, onsite start-up support and training, and any future training if required.

Download this product sheet here or browse our of library of other product sheets and case studies here. For more information on how Smart Tools work and their applications, click here.

Share this Post