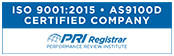

PROBLEM – Fabricate a 52” long by 12” dia. inlet duct using a clean tooling solution with the lowest up front capital cost and equal or better composite part cost.

OPPORTUNITY – Deliver a mandrel solution that requires lower up front cost than a multi-piece metal mandrel and can be deployed with both prepreg and dry carbon fiber with resin infusion to make the composite part.

SOLUTION – A Smart Tool that acts as a mandrel during cure was used to produce a UAV inlet duct that has lower up front cost than a multi-piece mandrel, is compatible with both prepreg & dry carbon fiber/VARTM manufacturing, and resulted in equivalent composite part performance and lower cost.

QUOTED SOLUTIONS

The customer was quoted both a multi-piece metal mandrel solution at $75,000 and a Smart Tool that acts as a mandrel solution at $40,000.

SMART TOOLING PROCESS

The Smart Tool that acts as a mandrel had a release film pre-applied, allowing the layup process to begin right away. The Smart Tool is rigid at layup, allowing prepreg to be directly applied to the Smart Tool, making layup easy.

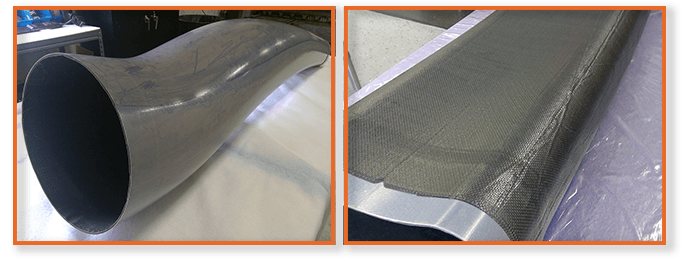

After lay up is finished, the applied prepreg and Smart Tool is vacuum bagged, and placed in an autoclave for a 9 hour cure cycle

Once the cure is complete, the consumable material is removed and the cured composite and Smart Tool are placed in an oven. Once the temperature is above 325°F (162°C), the Smart Tool that acts as a mandrel during cure is extracted from the composite part and put into a heated reforming mold, a vacuum bag is pulled through the Smart Tool and sealed to the mold, vacuum is applied, and the mold and Smart Tool are cooled, resulting in a Smart Tool with original geometric tolerance and ready to make another inlet duct.

RESULTS

Overall, the Smart Tool solution that acts as a mandrel tooling cost was a 47% savings. The Smart Tools that act as mandrels during cure are also compatible with hand applied carbon fiber prepreg, and hand-applied braided socks and vacuum-assisted resin transfer molding (VARTM).

This flexibility allows the UAV inlet duct to be made with significant savings, and in this case, reduce composite part costs from about $6,000 using hand applied prepreg, down to $3,100 using dry carbon fiber and epoxy infusion, a 48% savings.

Smart Tooling provides formable, reusable tooling solutions for manufacturing composite parts with complex geometries for the aerospace & defense industry. Smart Tools improve quality, reduce labor hours, decrease consumables, and increase throughput – essentially, Smart Tools enable the manufacturing of composite parts better, cheaper, and faster.

Smart Tooling’s Shape Memory Polymers are designed to be aerospace-grade RIGID epoxies at room temperature, and highly FLEXIBLE elastomers when heated, eliminating the need for expensive, laborious, tedious, dirty, and challenging solutions such as melt-out foam, metal breakdown tools, rubber bladders, or washout tooling.

We deliver comprehensive solutions for the manufacture of your composite part, including custom tooling engineering and design, fabrication of molds, Smart Tooling fabrication, initial composite part manufacturing, custom standard operating procedures, onsite start-up support and training, and any future training if required.

Browse our of library of other case studies and applications. For more information on how Smart Tools work and their applications click here.

Share this Post